| Robotturn XS-Series | XS125 | XS150 |

| BED TYPE | slant | slant |

| MAX. SWING DIAMETER | 300 mm | 350 mm |

| MAX. TURNING DIAMETER | 270 mm | 350 mm |

| MAX. TURNING LENGTH | 330 mm | 420 mm |

| MAX. BAR THROUGH-HOLE | 26 (35-39) mm | 40 (45) mm |

| SPINDLE THROUGH HOLE | 48 mm | 52 (56) mm |

| X-AXIS TRAVEL | 420 mm | 420 mm |

| Z-AXIS TRAVEL | 330 mm | 330 mm |

| X/Z AXIS | 20 m/min | 20 m/min |

| SPINDLE NOSE SIZE | A2-5 | A2-5 |

| SPINDLE SERVO MOTOR POWER | 3.7/5.5 kW | 5.5/7.5 kW |

| SPINDLE SPEED RANGE | 0~5000 (opt 6000) rpm | 0~5000 (opt 6000) rpm |

| WORK PIECE CLAMPING METHOD | 36 collet | 42 collet |

| WORK PIECE CLAMPING METHOD | 5” hydraulic chuck | 6″ hydraulic chuck |

| NUMBER OF TOOLS | 5 PCS | 5 (3+8 with turret) |

| TOOLHOLDER TYPE | T-slot bladerow (+ turret opt) | T-slot bladerow (+ turret opt) |

| ROTARY TOOLS | +spindle head (opt) | +spindle head (opt) |

| TOOLHOLDER CENTER HEIGHT IN RADIAL | 62 mm | 62 mm |

| TOOL SIZE | 20*20 mm | 20*20 (25*25 opt) |

| BORING ROD DIAMETER | 25 mm | 25 mm |

| X/Z AXIS REPEATING POSITIONING ACCURACY | 2µm | 2µm |

| COOLING TANK CAPACITY | 120 L | 120 L |

| HYDRAULIC TANK CAPACITY | 60 L | 60 L |

| REQUIRED ELECTRIC POWER | 12 kVA | 14 (15 with turret) kVA |

| HEIGHT FROM FLOOR TO SPINDLE CENTER | ≈1070 mm | ≈1070 |

| OVERALL SIZE (L*W*H) | 1850*1750*1750 mm | 1850*1750*1750 mm |

| NET WEIGHT WITHOUT OPTIONS AND ROBOT | ≈2400 kg | ≈2400 (2600 with turret) |

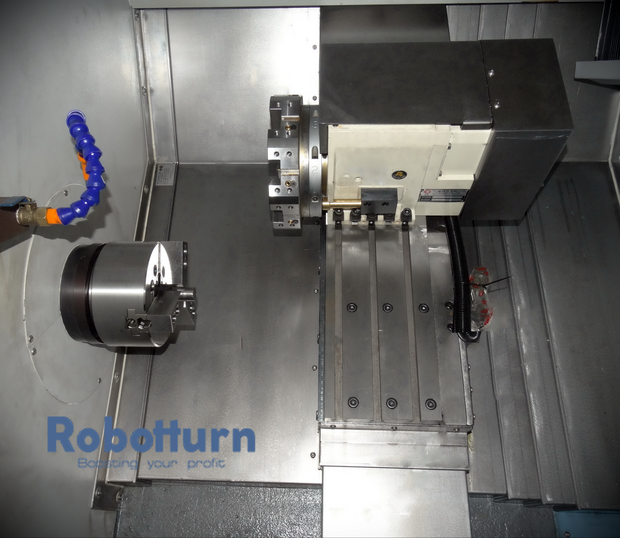

XS-Series : HIGH SPEED HIGH PRECISION CNC TURNING CENTERS

SLANT bed workhorse with high speed tool-change or turret or combined available

Our new generation compact turning centers machines incorporate a wide range of enhancements that make Robotturn lathes better than ever. Our engineers reviewed and improved all aspects including motion control, integration of automation systems for material handling, coolant containment, chip evacuation, ergonomics, and serviceability – to create the highest quality, most reliable turning centers machine tools available.

• High Performance combined with compact design

• High flexibility: bar and chuck work

• Option for automation peripherals and software designs to meet any need.

Packed with industry leading technology and top-quality components, the Robotturn® XS-series combine power, strength, and speed to bring you the Ultimate Machining Power. These high speed machines will easily accomplish the demanding turning applications of today and tomorrow. Furthermore, with available live tooling and C-axis capabilities; milling, turning applications may be completed in one single machine.

The new design provides smooth chip disposal and easier operator access. Steel way covers and special steel wipers moulded with industrial strength rubber are used for durability. Fully enclosed splashguards keep chips and coolant contained for a safe clean working environment. The auto lubrication system delivers metered amounts of lubrication to the slide ways, ball screws, and vital components. Distribution is automatically shut off during idling to prevent waste.

COMPACT AND HIGHLY RIGID STRUCTURES

MAXIMUM STRENGTH CONSTRUCTION

The XS range consists of a rigid single piece slant (inclined) bed structure made of high quality cast iron featuring high stability and good vibration dampening capacity.

Major structural components have been combined into one solid platform. The low center of gravity 45˚ slantbed design provides the most rigid foundation possible for the headstock, turret, and tailstock.

By using Finite Element Methods ( FEM ), optimal reinforce ribbings are directly cast into the one-piece bedstructure. Mechanical rigidity has been increased by more than 20% when compared to conventional designs.The Robotturn XS series is capable of performing heavy-duty turning and maintaining long-term high-precisionaccuracy. More rigidity also means extended tool life.

Built to withstand years and years of rigorous high production turning, the heavily ribbed, one-piece,thermally balanced bed and casting parts are of "Meehanite" casting. The 45 degrees true slant bed designfurther provides superior support for the headstock, turret, and tailstock, thus, creating the rigidity neededfor long-term high precision turning and efficient chip removal.

The headstock is mounted on the same surface of the guide ways. This design shortens the transmission path of cutting force and stabilizes the cutting capability.

Precision hand scraped

Contact surfaces of headstock and ball screw bearing housings with the machine bed are precision hand scraped to provide maximum assembly precision, structural rigidity, and load distribution.

ULTIMATE TURNING POWER

The heavily ribbed, one-piece thermally balanced headstock and heat dispensing fins evenly dispense heat to reduce deformation, there fore, increasing machining accuracy.

Standard rigid tapping feature provides high-speed precision tapping without the use of floating tap holders. Set-up is easier and depth of thread more accurate, permitting maximum productivity for tapping operations.

The precision direct belt drive system provides greater spindle control, flexibility and serviceability. Pulley ratios fine tune the motor's maximum RPM to match the spindle's maximum RPM,which result in full output at the lowest RPM possible.

XT models are available with built-in spindle motors,which eliminate traditional belts and pulleys. This advanced system provides faster spindle response, reduces vibration and power loss, which translate to faster cycle times, higher accuracy, and lowers maintenance costs.

Belt driven or built-in direct driven spindle

The non-cutting and dwell time has been innovatively saved compared to the existing model by adapting a high performance of AC spindle motors

Optional available is our Direct Drive Spindle Motor, which ensures smooth vibration free option (essential for the manufacture of super precision components) and provides improved surface finish and roundness.

With the trend toward greater productivity and more compact machine design, the use of integrated motor spindles is becoming more and more commonplace. Their dynamic rigidity and low vibration tendency make a further leap in machining quality possible. Their ability to accelerate and operate at high speeds shortens the machining time, thereby increasing the productivity of the machine.

Benefits and characteristics

■ Excellent quality of surface finish, maximum concentricity and high dynamic rigidity

■ Shorter acceleration and deceleration times and high maximum speeds

■ Compact design