SwissTek A8M-Series CNC Swiss Type Automatic Lathe Technical specifications

2 Models - SwissTek-20A8M - SwissTek-26A8M

| SwissTek A8M-Series CNC Swiss Type Automatic Lathe Technical specifications | |||||

| SwissTek A8M-Series | 20A8M | 26A8M | |||

| NC device | 220TB | 220TB | |||

| Power source | 380VAC | 380VAC | |||

| Lathe rated power | Kw | 11 | 11 | ||

| Machin i ng range | Machin i ng range dia. | mm | Φ 20 | Φ26 | |

| Main spindle max clamping dia. | mm | Φ 20 | Φ26 | ||

| Max feed length (once) | mm | Max 240 | Max 240 | ||

| Main/sub spindle | Main spindle power | Kw | 2.2/3.7 | 2.2/3.7 | |

| Sub spindle power | Kw | 1.5/2.2 | 1.5/2.2 | ||

| Main spindle max through hole dia. | mm | Max Φ27 | Max Φ27 | ||

| C axis resolution | ° | C1/C2 0.001° | C1/C2 0.001° | ||

| Main/sub spindle rev speed | rpm | Max10000/12000 | Max10000/12000 | ||

| Sub spindle max clamping dia. | mm | Max Φ20 | Max Φ26 | ||

| Sub spindle max through hole dia. | mm | Max Φ 27 | Max Φ27 | ||

| Main spindle max travel | With guide bush | mm | 2 40 | 240 | |

| Non guide bush | mm | 3 55 | 355 | ||

| Max tool installed qty. | pcs | 2 6 | 26 | ||

| OD Turning tool | Qty.×Model | 6 × □ 12 | 6×□12 | ||

| Cross live tool | Qty.×Model | 4 ×ER1 6 | 4×ER16 | ||

| Drilling dia. | mm | Max Φ 10 | Max Φ10 | ||

| Tapping/Threading die dia. | Max M 8 | Max M8 | |||

| Live tool rev speed | rpm | Max 4000 | Max 4000 | ||

| Live tool power | Kw | 0.75 | 0.75 | ||

| End-face tool | Fixed | Qty.×Model | 4×ER16 | 4×ER16 | |

| ( Main spindle ) | Drilling dia. | mm | Max Φ10 | Max Φ10 | |

| Tapping/Threading die dia. | Max M8 | Max M8 | |||

| Back end-face tool | Fixed | Qty.×Model | 4×ER16 | 4×ER16 | |

| ( Sub spindle ) | Drilling dia. | mm | Max φ10 | Max Φ10 | |

| Tapping/Threading die dia. | Max M8 | Max M8 | |||

| Live | Qty.×Model | 4×ER16 | 4×ER16 | ||

| Drilling dia. | mm | Max Φ8 | Max φ8 | ||

| Tapping/Threading die dia. | Max M6 | Max M6 | |||

| Live tool rev speed | rpm | Max 4000 | Max 4000 | ||

| Live tool power | Kw | 0.75 | 0.75 | ||

| Rapid feed speed | m/min | 30(Z1/Z2/X2/Y1) | 30(Z1/Z2/X2/Y1) | ||

| 24(X1),15(Y2) | 24(X1),15(Y2) | ||||

| Feed motor power | Kw | 0.75(Z1/Z2/X1/X2/Y1) | 0.75(Z1/Z2/X1/X2/Y1) | ||

| 0.5(Y2) | 0.5(Y2) | ||||

| Cutting oil pump power | Kw | 0.75 | 0.75 | ||

| Main/sub spindle cooling oil pump power | Kw | 0.12 | 0.12 | ||

| Lubricating oil pump power | Kw | 0.004 | 0.004 | ||

| Max collecting length of workpieces collect box | mm | 80 | 80 | ||

| Main/sub spindle center to the bottom of lathe body | mm | 1050 | 1050 | ||

| Cutting oil tank volume | L | 180 | 180 | ||

| Net weight | Kg | 2700 | 2700 | ||

| Dimensions(L×W×H) | mm | 2180×1280×1775 | 2180×1280×1775 | ||

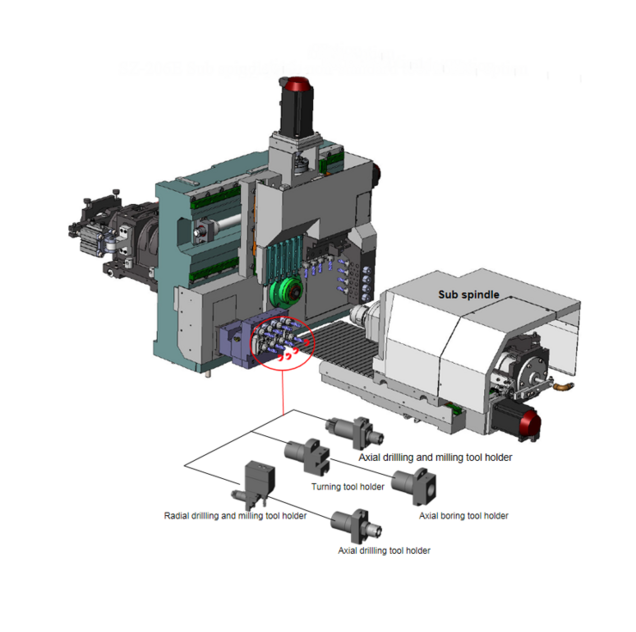

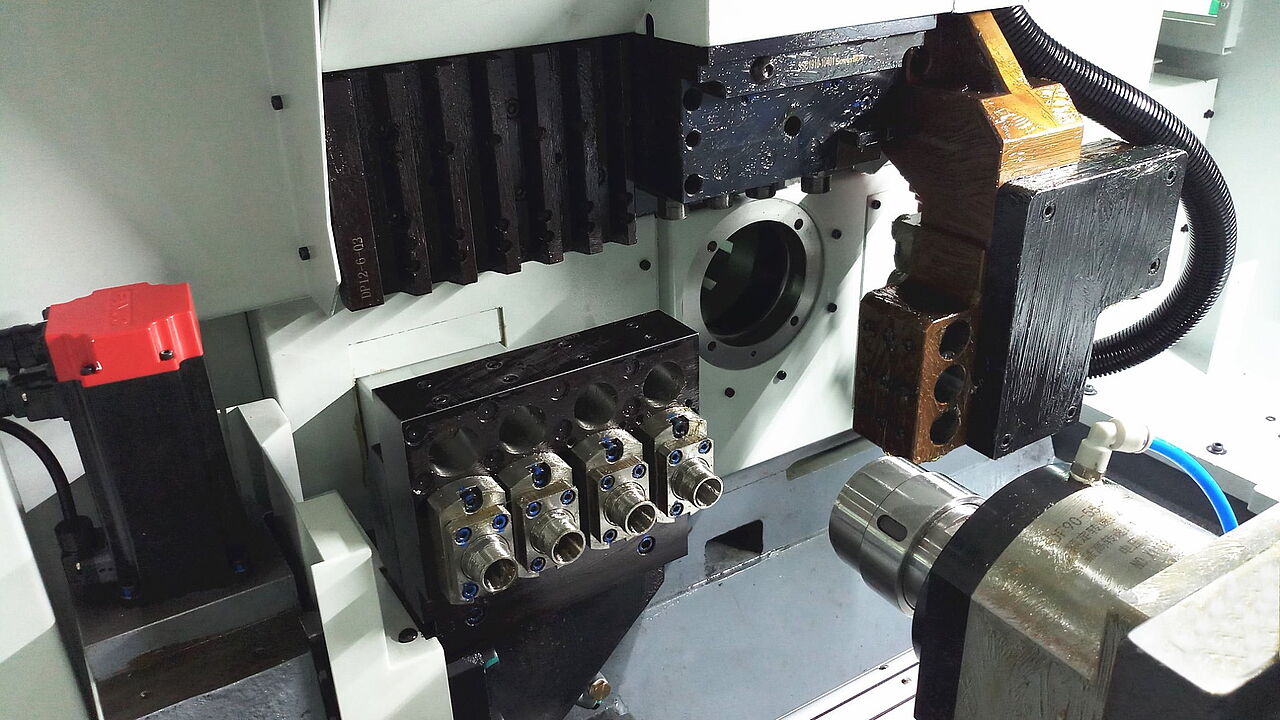

Special tooling options Main spindle For SwissTek A8M

Y2-axis Machining Capability For Subspindle

Backmachining Versatility in 4-axis

With the optional Y2-axis function the SwissTek A8M-Series can proceed eccentric drilling, tapping, milling and different kind of complicated machining with the back spindle.

Rear-end tool holder is available with 8 tools of ER-16 live tools which driven by 1.0 kW AC servo motor with high torque output.

Simultaneous Machining, Double Y-axis for Complex Machining For complex precision parts this machine has simultaneous machining capability on the main and sub-spindles. There is also +/-30 mm of travel on the Y2 backworking module which is equipped with 4/8 driven tools. The SwissTek A8M can accommodate a variety of tools for overlapping and simultaneous operations.

Both the main and sub-spindle, feature full C-axis capabilities and can perform fast and accurate backside machining. This Swiss-style design with or without guide bushings delivers versatility, rigidity, and high performance, perfect for short runs of complex parts made complete in a single set-up.