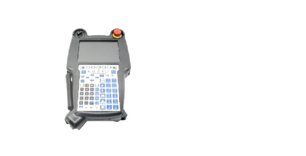

What does this button do on my robot controller?

Is this your operator's daily problem?

Is this not a question your machine operator is daily confronted with?

Perhaps you recognize the complex controller shown here?

Perhaps you find it scary to look at, let alone interact with?

It clearly radiates a complex and technical nature of interaction and understanding.

You most likely need extensive training to control that thing - right?

Time for a change

Robot graphic HMI - Human Machine Interface

The complex pendant controller every robot maker is using is a huge bottleneck in most of the workshops.

The challenge for Us consisted of redesigning the interface of the Robot. Rather than a pendant with hundreds of unknown buttons, that has been the standard since forever, we took a very innovative decision to use an interactive touchscreen with very simple graphic interaction, to control the robot-loader and kept the Lathe controller as standard.

This means that the lathe can be used as standard CNC machine to make one single piece manually without interaction of the robot. All possible loading-unloading cycles are pre-programmed and the operator need only to fill in some of the values of the different stop/start points in the graphic interface. Simpler is not possible!

No robotics experience is required for the graphical robot controller. Our robot is already completely pre-programmed, so that the operator only needs to enter a few parameters.

This means a new series can be started in a matter of minutes.

G-code list with extended functions standard in Robotturn

Our controller offers more than the Fanuc controller reference controller

| Fanuc Ot G-Code List | |||

| Fanuc | Robotturn | ||

| G Code | Extra G-code | Function | |

| G00 | Positioning (Rapid traverse) | ||

| G01 | Linear interpolation (Cutting feed) | ||

| G02 | Circular interpolation CW or helical interpolation CW | ||

| G02.1 | Elliptical cutting (clockwise) (G02.1) | ||

| G02.2 | Parabolic cutting (clockwise) (G02.2) | ||

| G03 | Circular interpolation CCW or helical interpolation CCW | ||

| G04 | Dwell | ||

| G07.1(G107) | Cylindrical interpolation | Cylindrical interpolation (G07.1) | |

| G08 | Advanced preview control | ||

| G10 | Programmable data input | ||

| G11 | Programmable data input cancel | ||

| G12.1(G112) | Polar coordinate interpolation mode | Activate polar coordinate interpolation (G12.1) | |

| G13.1(G113) | Polar coordinate interpolation cancel mode | ||

| G17 | X Y plane selection | ||

| G18 | Z X plane selection | ||

| G19 | Y Z plane selection | ||

| G20 | Input in inch | ||

| G21 | Input in mm | ||

| G20 | External radius / internal radius lathing and cutting cycle (G20) | ||

| G21 | Threaded lathing and cutting cycle (G21) | ||

| G21.2 | Threaded lathing and cutting mid-phase blade entry cycle (G21.2) | ||

| G22 | Stored stroke check function on | ||

| G23 | Stored stroke check function off | ||

| G24 | Edge and surface lathing and cutting cycle (G24) | ||

| G25 | Spindle speed fluctuation detection off | ||

| G26 | Spindle speed fluctuation detection on | ||

| G27 | Reference position return check | ||

| G28 | Return to reference position | ||

| G30 | 2nd, 3rd and 4th reference position return | ||

| G31 | Skip function | ||

| G32 | Thread cutting | ||

| G33 | Thread cutting (G33) | ||

| G34 | Variable—lead thread cutting | ||

| G36 | Automatic tool compensation X | ||

| G37 | Automatic tool compensation Z | ||

| G40 | Tool nose radius compensation cancel | ||

| G41 | Tool nose radius compensation left | ||

| G42 | Tool nose radius compensation right | ||

| G50 | Coordinate system setting or max. spindle speed setting | ||

| G50.3 | Workpiece coordinate system preset | ||

| G50.2(G250) | Polygonal turning cancel | ||

| G51.2(G251) | Polygonal turning | ||

| G52 | Local coordinate system setting | ||

| G53 | Machine coordinate system setting | ||

| G54 | Workpiece coordinate system 1 selection | Operating coordinate system configuration (G54~G59.9) | |

| G55 | Workpiece coordinate system 2 selection | ||

| G56 | Workpiece coordinate system 3 selection | ||

| G57 | Workpiece coordinate system 4 selection | ||

| G58 | Workpiece coordinate system 5 selection | ||

| G59 | Workpiece coordinate system 6 selection | ||

| G59.1 - G59.9 | 9 extra coordinate systems | ||

| G65 | Macro calling | ||

| G66 | Macro modal call | ||

| G67 | Macro modal call cancel | ||

| G68 | Mirror image for double turrets ON | ||

| G68.2 | Tilted surface processing (G68.2) | ||

| G69 | Mirror image for double turrets OFF | ||

| G70 | Finishing cycle | ||

| G71 | Stock removal in turning | ||

| G72 | Stock removal in facing | Duplex cutting cycles (G72~G78) | |

| G73 | Pattern repeating | ||

| G74 | End face peck drilling | ||

| G75 | Outer diameter/internal diameter drilling | ||

| G76 | Multiple threading cycle | ||

| G77 | Outer Diameter/Internal Diameter Drilling Cycle (G77) | ||

| G78 | Multiple Thread Cutting Cycle (G78).. | ||

| G80 | Canned cycle for drilling cancel | ||

| G83 | Cycle for face drilling | ||

| G84 | Cycle for face tapping | ||

| G86 | Cycle for face boring | ||

| G87 | Cycle for side drilling | ||

| G88 | Cycle for side tapping | ||

| G89 | Cycle for side boring | ||

| G90 | Outer diameter/internal diameter cutting cycle | ||

| G92 | Thread cutting cycle | ||

| G92.1 | Default absolute zero coordinated system (G92.1) | ||

| G93 | Inversed time feed (G93) | ||

| G94 | Endface turning cycle | ||

| G96 | Constant surface speed control | ||

| G97 | Constant surface speed control cancel | ||

| G98 | Per minute feed | ||

| G99 | Per revolution feed | ||

| G114.1 | Spindle synchronization function (G114.1) | ||

| G114.3 | Spindle bearing function (G114.3) | ||

Do you want to know all about our Robotturn ?

Call "Patrick" +32 (0)475736351 (Belgium)

He will explain you all about our Machines.

(Nederlands - Français - English - Deutsch)

CNC robotics, CNC robots, machine tending robots, loading and unloading robots, machining center robotics, turning center robotics, robotic turning centers, robotic CNC lathes, robotic CNC vertical mills, robotic machining centers, robotic part loading and unloading, robotic machine tending, unmand turning, unmanned turning production, cnc lathe with gantry loader, full unmanned production, lathe gantry loader, automated parts loading for CNC lathes.